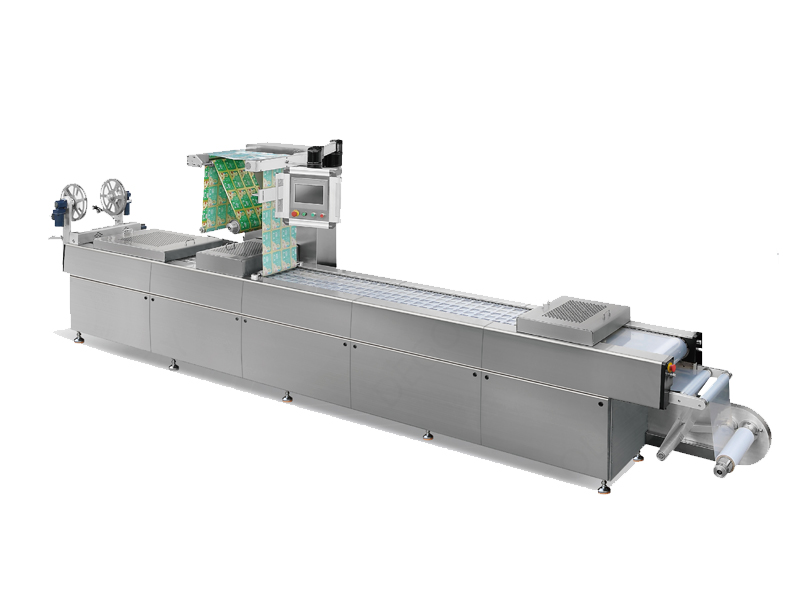

Thermoforming Packaging Machine

Capacity: 3000-12000 pcs/h

Minimum size: 3500×1000×1800 mm

Multiple sets of molds can be customized

International brand spare parts

Application

Fresh meat, frozen meat, sausages, meat products, fresh fish, frozen fish, seafood, poultry, medical devices…

Introduction

Firstly, the flexible film is heated and thermoformed by the thermoforming packaging machine. The product to be packaged is then placed into the molded container. The top film covers the product, and after vacuuming, a vacuum environment is created inside the package. This packaging method isolates the packaged product from external air, effectively preventing the entry of oxygen, moisture, corrosion, and mold, thereby extending the shelf life.

Feature

· Mitsubishi PLC control system and fault alarm system.

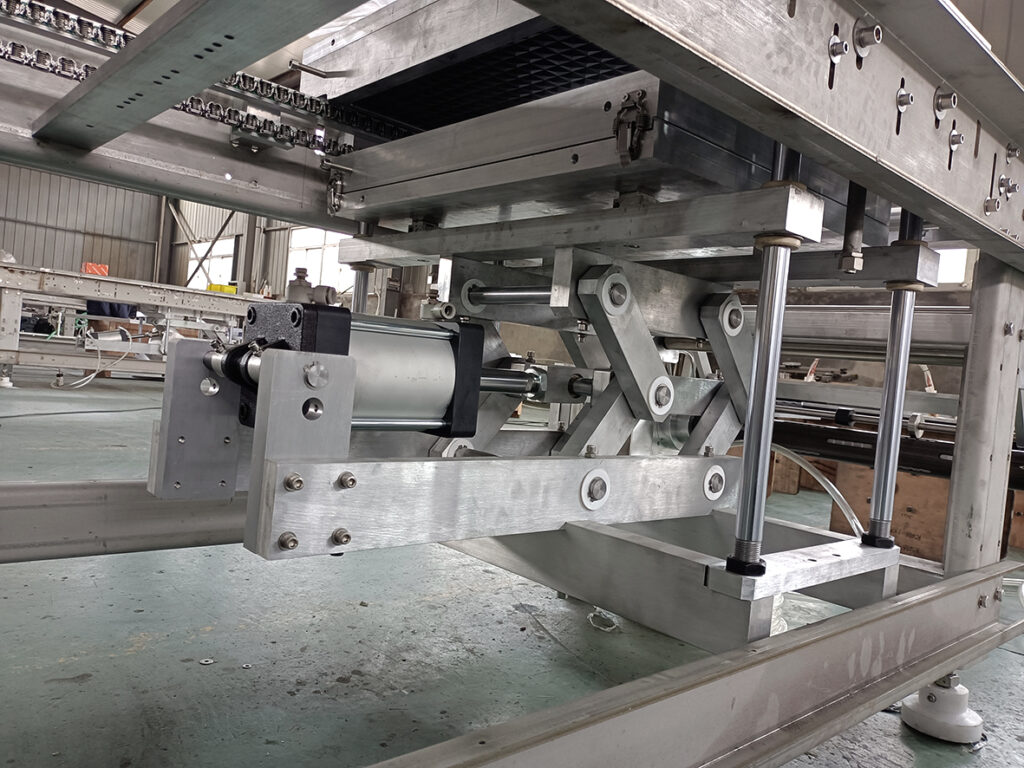

· Italian Regina lubrication-free chain can make the movement of the film more accurate.

· An automatic film correction system ensures stable operation.

· Both top and bottom films can undergo thermoforming.

· Various film molds can be customized for personalized packaging.

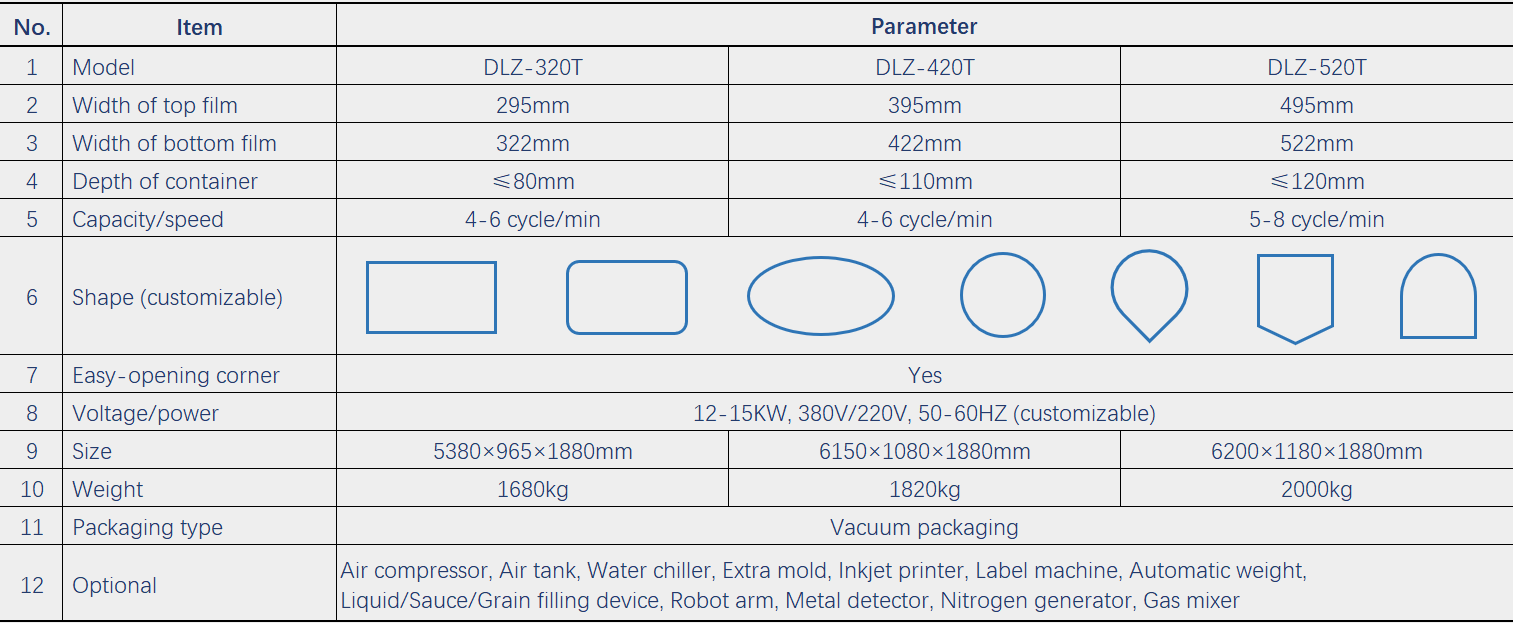

Parameter

Details

Related products

MAP(modified atmosphere packaging) machine

Skin packaging machine with tray