Double Chamber Vacuum Packaging Machine

Model: DZ-600

Chamber size: 1710×650×120 mm

Seal distance: 518 mm

Size: 1500×780×950 mm

Application

Fruit, dried fruit, seafood, food, sausage, medical devices…

Principle

The principle of the double chamber vacuum packaging machine is that one vacuum cover is used to work alternately on the two vacuum chambers. When one vacuum chamber is vacuuming, the other vacuum chamber can be placed by packaging. This way can improve work efficiency. Microcomputer program control can adjust the vacuum range and sealing temperature. Vacuum, nitrogen filling and sealing are completed at one time. The machine has the advantages of simple operation, high working efficiency, high configuration, low failure rate and easy maintenance.

This machine adopts thick stainless steel flanged welding. The body is also made of stainless steel. It guarantees corrosion protection and aesthetics.

Feature

· The vacuum lid is designed in a convex and concave shape. The speed of vacuuming is increased

· High quality chips. The machine runs more stably.

· Heating device. The internal spring of the heating device is adjusted by copper wire. It can increase the service life.

· Universal wheel. Universal wheel with brake function, easy to move and fix

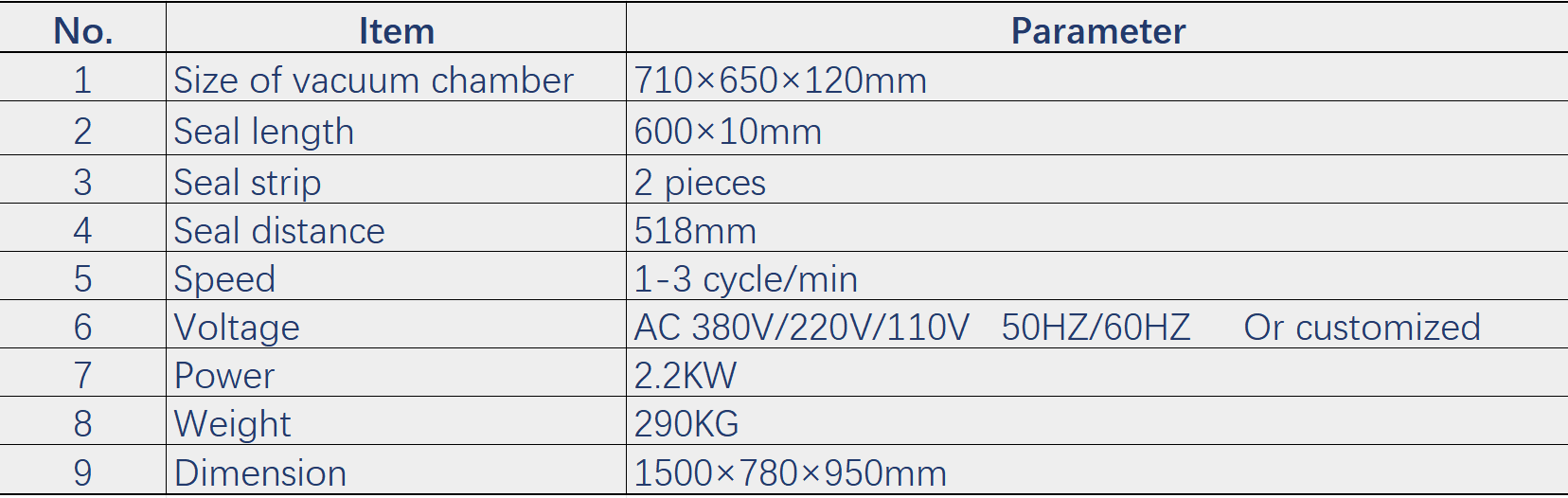

Parameter

Related products

MAP(modified atmosphere packaging) machine

Skin packaging machine with tray